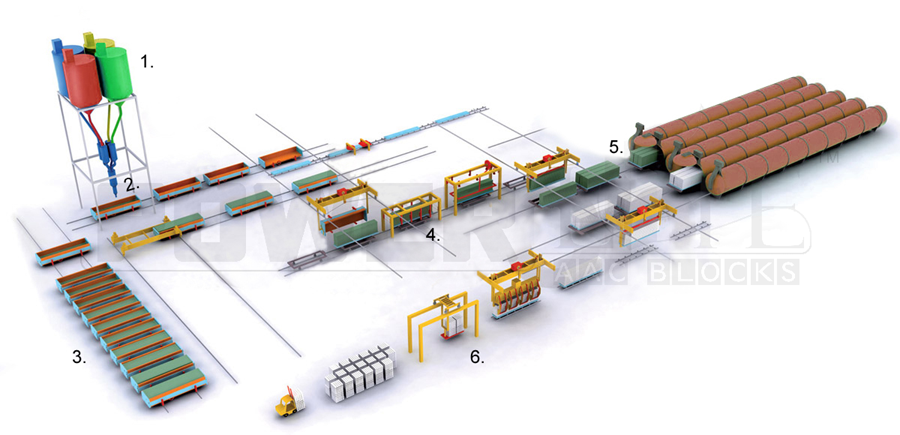

Manufacturing Process

1. Preparation and storage of raw materials :

First, Sand is grinded by ball mill and converted into slurry to be stored in the underground slurry tank. Lime is crushed and stored in the lime silo in powdered form, Cement and aluminium powder is stored in the respective silos.

2. Batching, Mixing, Pouring :

Sand slurry, lime powder, cement and aluminium powder are then weighed and then poured into pouring mixture for mixing and finally poured into mould box

3. Pre-curing :

The mould box is brought to a standstill. Due to hydrogen produced due to chemical reactions between aluminium, lime and water, the mixed slurry expands in the mould converting it into what is called a green cake.

4. Cutting :

Machines transport the mould to the cutting station where the crane manipulators demould the mould box. The cake is then passed through a cutting wire mesh controlled by hydraulic systems which cuts the entire cake into desired dimensions of AAC blocks.

5. Autoclaving :

The cake enters a high pressure, high temperature steam chamber made of steel pipe called an Autoclave and stays there for a period of 8-10 hours during which the AAC receives its strength and density.

6. Stacking and Dispatch :

After coming out from the autoclave, the AAC blocks are stacked in the stocking yard and is ready for dispatch.